Similar to the 2D parameters, this feature must first be enabled by clicking on the 1D Line roughness button under the Analysis section.

The software draws a line across the Top View image, indicating the location from which the profile data is currently being calculated. By default this line will be oriented horizontally. To alternate between horizontal, vertical, or diagonal line segments, use the radio buttons under Profile Orientation in the side panel.

Clicking and dragging on the line will move the line in the X or Y direction, while clicking and dragging on the endpoints changes to diagonal mode.

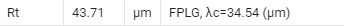

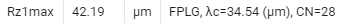

The Settings cog works similar to 3D Areal Parameters, using check boxes to select which parameters to display. In addition, there are also the Filter, Cutoff Length, and Number of Samples settings which affect how the resulting values are calculated.

First, select the Filter method to be used; Gaussian, Spline (β = 0.625242), or Spline (β = 0). For a more in-depth explanation of these filtering methods, see the Filter article in the Appendices section.

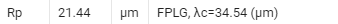

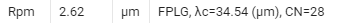

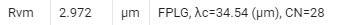

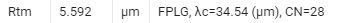

Next, set a cutoff wavelength to use for the filter. The values available are calculated based on the loaded image. The correct value for the application will vary, however the table excerpted from ASME B46.1 2D below can give a rough guideline based on expected roughness of the surface.

Roughness |

Cutoff |

|||

Rz (µm) |

Ra (µm) |

Rz (µin) |

Ra (µin) |

λc (µm) |

< 0.025 - 0.1 |

> 0.006 - 0.02 |

>1 - 3.9 |

>0.24 - 0.79 |

80 |

0.1 - 0.5 |

0.02 - .1 |

3.9 - 19.7 |

0.79 - 3.9 |

250 |

.5 - 10 |

.1 - 2 |

19.7 - 393.7 |

3.9 - 78.7 |

800 |

10 - 50 |

2 - 10 |

393.7 - 1969 |

78.7 - 393.7 |

2500 |

50-200 |

10-80 |

1968.5 - 7874 |

393.7 - 3149.6 |

8000 |

Finally, set the Number of Samples to use. By default, this value is set to Max Samples, but can be changed to a user defined value. The number used refers to the number of segments the selected line is broken into based on the cutoff length selected. If the User Specified option is used, it uses the lesser of either the entered number, or the maximum available number of samples.

The table below provides a quick reference for each parameter measurement.

Parameter |

2D Profile - ASME B46.1 2D |

|

Maximum peak height+ |

|

Maximum valley depth+ |

|

Maximum height* |

|

Maximum peak to valley height+ |

|

Maximum peak height* |

|

Maximum valley depth* |

|

Maximum height* |

|

Maximum sample peak to valley height |

|

Arithmetic mean deviation+ |

|

Root mean square deviation+ |

|

Skewness+ |

|

Kurtosis+ |

Parameter |

2D Profile - ISO 4287 Amplitude |

|

Maximum peak height* |

|

Maximum valley depth* |

|

Maximum height* |

|

Total height+ |

|

Arithmetic mean deviation* |

|

Root mean square deviation* |

|

Skewness* |

|

Kurtosis* |

|

Maximum sample peak height |

|

Maximum sample valley depth |

|

Maximum sample peak to valley height |

* Averaged over sample lengths.

+ Calculated over evaluation length.